Sewer Backup FAQs

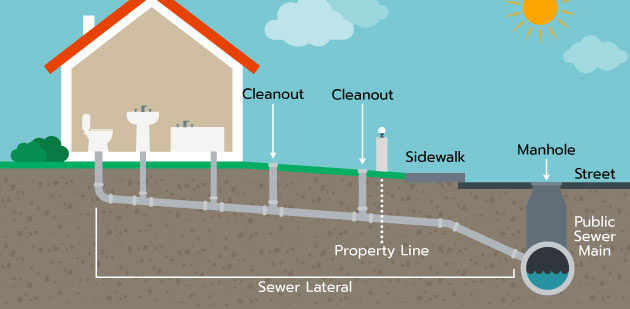

What is a sewer lateral?

Every building has a sewer lateral. The sewer lateral is the main pipe that connects the building to the city’s sewer system or your septic tank. Laterals for homes are typically 4″-6″ diameter, buried 6-12 feet below the ground surface, and usually made of clay, cast iron, or PVC, depending on the year of construction.

What is a sewer backup?

A sewer backup is a serious problem that can occur when sewage from a building flows backward into the building rather than away. Incorrect flow can be caused by a pipe blockage, resulting in significant damage and health risks. The backup typically occurs in the lowest level (basement), where sewage may flow through a floor drain or shower drain and can flood the area with sewage. Sewage can pose health risks to occupants and damage the area’s flooring, walls, and anything else.

Sewer backups are usually caused by tree roots working their way into the sewer lateral. Many buildings have trees in the front yard near or just above the sewer lateral.

Consequently, this tree receives water and nutrients from the sewer. However, its roots obstruct the sewage flow, trapping debris such as toilet paper and creating blockages. Subsequently, these blockages inhibit the sewage from flowing away from the building, allowing it to build up and eventually become visible in the building. To resolve this sewage backup, a sewer cleaning device is necessary to remove the roots and restore the regular flow of the pipe. However, this method can damage the sewer pipe and is only a temporary solution as the roots will grow back.

How can I eliminate a sewer backup?

Sewer pipe relining or replacing the sewer lateral can permanently resolve sewage backups. Relining the lateral provides a brand new single continuous pipe that prevents entry of tree roots and has a 50-year transferable warranty.

What is a sewer lateral collapse?

Many sewer laterals are well beyond their anticipated lifespan. Over time, tree roots, ground movement, and pipe corrosion can lead to sewer lateral collapse. If the sewer lateral collapses, the building will be habitable once the repair is complete, as sewage will no longer be able to drain away from the building.

Typically, the only want to fix a sewer lateral collapse is to dig a deep trench (>10′ deep) from the building to the city’s sewer main in the street and replace the lateral. This project will likely require removing anything in the path of the sewer lateral, including trees, bushes, landscaping, decks, etc. This type of project can be costly (>$20k-$60k) due to the required work and the cost of digging in the city’s right of way, which requires specialized permits and experience.

Mitigate the risk of sewer lateral collapse with a sewer video inspection to determine its condition. Relining the lateral eliminates the risk of catastrophic failure.

What is the life expectancy of sewer line materials?

One of three materials likely makes up existing home sewer lines. Before 1980, VCP and cast iron pipes were the norms for new construction. However, during the 1970s, PVC piping became increasingly popular, and by the 1980s, it had become the most–used material for new sewer lines.

The life expectancy of the sewer lateral is very dependent on local conditions (soil and water corrosivity, ground movement, and tree roots nearby). PVC, cast iron, and clay pipes come in 10′ or 20′ segments and are joined together with joints that have the potential for leakage if there is any movement.

Year of Construction

Most Likely Lateral Material

1880 – 1980

VCP (Vitrified Clay Pipe), Cast Iron or combination of the two

After 1980

PVC

Cast Iron

These pipes come in segments and are very heavy, and they have the lowest expected lifespan as they rust, corrode, and build up scale deposits that constrict the pipe over time.

Expected to last 50 years, cast iron pipes could be shorter-lived due to soil/water corrosion, tree roots, or ground movement. Cast iron pipes have the potential to last longer if there are no local adverse conditions.

Clay Pipes

These come in short segments and are very heavy. They typically last 50 years but could be less due to soil/water corrosion, tree roots or ground movement. Clay pipes are somewhat brittle and can crack with ground movement or root penetration.

Because the pipe segments are heavy and rigid, the joints don’t fit perfectly. These joints can leak, attracting tree roots to the water and nutrients. The porous clay material attracts tree roots. Clay pipes have the potential to last longer if there are no adverse local conditions because the clay pipe is resistant to corrosion and less prone to scale buildup.

PVC Pipes

They should expect to last 50–100 years before needing replacement, boasting the most extended lifespan. These pipes come in 10′ or 20′ segments and are flexible, relatively lightweight, and resistant to chemicals, corrosion, and scale buildup.

Sewer Lateral Material

Expected Lifespan from Date of Install in Years

Known Issues

Benefits

Notes

Vitrified Clay Pipe

50

Brittle; Ground movement can crack it and cause collapse. Potential for leakage at joints.

Resistant to corrosion and scale formation.

Lifespan is reduced if there are tree roots present or any ground movement; if ther are no roots or ground movement, pipe could last to 100 years.

Cast Iron

50

Rusting, corrosion will eventually create holes and pipe failure. Scale buildup will constrict pipe area. Potential for leakage at joints.

Lifespan is reduced if there are tree roots present or any ground movement.

PVC

50-100

Potential for leakage at joints.

Flexible

Cured in Place Pipe (CIPP) Reline

75-100 (includes 50-year transferable warranty)

None

Single continuous pipe. No joints. No root iintrusion, No corrosion, Flexible, not brittle.

Call for your video inspection quote, or click BOOK INSPECTION.

Expert Sewer Repair Serving Milwaukee, Madison and Southern Wisconsin

Milwaukee

Brookfield

New Berlin

Wauwatosa

Shorewood

Waukesha

Madison

Oak Creek

West Allis

West Milwaukee

Cudahy

Fox Point

Whitefish Bay

Janesville

Mequon

Germantown

Milwaukee County

Glendale

Brown Deer

Grafton

Beloit

Saukville

Cedarburg

Thiensville

West Bend

Greendale

Greenfield

Racine

Muskego

Mukwonago

Jackson

Hartford

Port Washington

Oconomowoc

Kenosha

South Milwaukee

Sussex

Pewaukee

Menomonee Falls

Franklin

Sheboygan

Sewer Backup FAQs

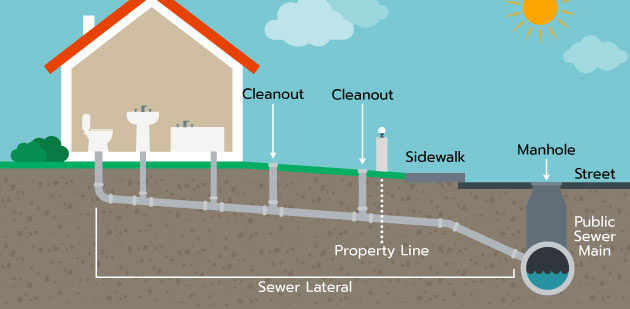

What is a sewer lateral?

Every building has a sewer lateral. The sewer lateral is the main pipe that connects the building to the city’s sewer system or your septic tank. Laterals for homes are typically 4″-6″ diameter, buried 6-12 feet below the ground surface, and usually made of clay, cast iron, or PVC, depending on the year of construction.

What is a sewer backup?

A sewer backup is a serious problem that can occur when sewage from a building flows backward into the building rather than away. Incorrect flow can be caused by a pipe blockage, resulting in significant damage and health risks. The backup typically occurs in the lowest level (basement), where sewage may flow through a floor drain or shower drain and can flood the area with sewage. Sewage can pose health risks to occupants and damage the area’s flooring, walls, and anything else.

Sewer backups are usually caused by tree roots working their way into the sewer lateral. Many buildings have trees in the front yard near or just above the sewer lateral.

Consequently, this tree receives water and nutrients from the sewer; however, its roots obstruct the sewage flow, trapping debris such as toilet paper and resulting in blockages. Subsequently, these blockages impede the sewage from flowing away from the building, leading to a buildup of sewage that eventually becomes visible in the building. To remedy this sewage backup, a sewer cleaning device is necessary to remove the roots and restore the regular flow of the pipe; yet, this method can damage the sewer pipe and is only a temporary solution, as the roots will grow back.

How can I eliminate a sewer backup?

Sewer pipe relining or replacing the sewer lateral can permanently resolve sewage backups. Relining the lateral provides a brand new single continuous pipe that prevents entry of tree roots and has a 50-year transferable warranty.

What is a sewer lateral collapse?

Many sewer laterals are well beyond their anticipated lifespan. Over time, tree roots, ground movement, and pipe corrosion can lead to sewer lateral collapse. If the sewer lateral collapses, the building will be habitable once the repair is complete, as sewage will no longer be able to drain away from the building.

Typically, the only want to fix a sewer lateral collapse is to dig a deep trench (>10′ deep) from the building to the city’s sewer main in the street and replace the lateral. This project will likely require removing anything in the path of the sewer lateral, including trees, bushes, landscaping, decks, etc. This type of project can be costly (>$20k-$60k) due to the required work and the cost of digging in the city’s right of way, which requires specialized permits and experience.

Mitigate the risk of sewer lateral collapse with a sewer video inspection to determine its condition. Relining the lateral eliminates the risk of catastrophic failure.

What is the life expectancy of sewer line materials?

One of three materials likely makes up existing home sewer lines. Prior to 1980, VCP and cast iron pipes were the standard for new construction; yet, during the 1970s, PVC piping began to gain traction, eventually becoming the go–to material for new sewer lines by the 1980s.

The life expectancy of the sewer lateral is very dependent on local conditions (soil and water corrosivity, ground movement, and tree roots nearby). PVC, cast iron, and clay pipes come in 10′ or 20′ segments and are joined together with joints that have the potential for leakage if there is any movement.

Construction Year: 1880 – 1980

Material: VCP (Vitrified Clay Pipe), Cast Iron or Combination of the two

After: 1980

Material: PVC

Cast Iron

These pipes come in segments and are very heavy, and they have the lowest expected lifespan as they rust, corrode, and build up scale deposits that constrict the pipe over time.

Expected to last 50 years, cast iron pipes could be shorter-lived due to soil/water corrosion, tree roots, or ground movement. Cast iron pipes have the potential to last longer if there are no local adverse conditions.

Clay Pipes

These come in short segments and are very heavy. They typically last 50 years but could be less due to soil/water corrosion, tree roots, or ground movement. Clay pipes are somewhat brittle and can crack with ground movement or root penetration.

Because the pipe segments are heavy and rigid, the joints don’t fit perfectly. These joints can leak, attracting tree roots to the water and nutrients. The porous clay material attracts tree roots. Given that clay pipes are resistant to corrosion and less prone to scale buildup, they have the potential to last longer if there are no local adverse conditions.

PVC Pipes

They should expect to last 50–100 years before needing replacement, boasting the most extended lifespan. These pipes come in 10′ or 20′ segments and are flexible, relatively lightweight, and resistant to chemicals, corrosion, and scale buildup.

Call for video inspection quote.

Or

Expert Sewer Repair Serving Milwaukee, Madison and Southern Wisconsin

Milwaukee | Brookfield | New Berlin | Wauwatosa | Shorewood | Waukesha | Oak Creek | West Allis | West Milwaukee | Cudahy | Fox Point | Whitefish Bay | Mequon | Germantown | Milwaukee County | Glendale | Brown Deer | Grafton | Saukville | Cedarburg | Thiensville | West Bend | Greendale | Greenfield | Muskego | Mukwonago | Jackson | Hartford | Port Washington | Oconomowoc | South Milwaukee | Sussex | Pewaukee | Menomonee Falls | Franklin | Madison | Janesville | Beloit | Racine | Kenosha | Sheboygan